It was in the spring of 2014 that I started Hitotsuya Dyeing and Weaving Farm to cultivate plants related to dyeing and weaving. At first, we rented a corner of a communal kitchen garden in the city, and it was a small space that could hardly be called a “farm.” In the fall of the same year, the area increased slightly, and in the spring of the following year, various dye plants were cultivated.

Then, in the summer of 2018, we purchased farmland and an old folk house in Iga City (Mie Prefecture) and tried to start cultivating dyed and woven plants in earnest, but due to movement restrictions due to the coronavirus that began to spread from the end of the year. Activities were suspended. It wasn’t until the fall of 2020 that we were able to reopen.

Now, several years later, Hitotsuya is gradually increasing the variety and quantity of dyeing and weaving plants it cultivates, and is aiming to sell these products.

Hitotsuya Dyeing and Weaving Farm

Cultivated land was once abandoned due to a lack of successors and an aging population. The work of cutting down overgrown pampas grass and bamboo and removing their roots is hard work that is more similar to “cultivation” than “regeneration.” In this regenerated field, we sow indigo and cotton seeds, plant mulberry seedlings, and operate Hitotsuya Dyeing and Weaving Farm, where we cultivate only plants related to dyeing and weaving.

▼ Regeneration of abandoned cultivated land. The work began with cutting down the bamboo that covered the area.

▼ Cotton (Japanese cotton) was the first to be grown on the regenerated arable land.

▼ In total, we harvested about 2 kg of cotton the first year.

At HITOTSUYA, harvested cotton is “wadded” and “wadding” is done at a futon store before being made into yarn using a Meiji-era spinning machine called a “garabo” (restoration machine). After dyeing, hand-weaving, and sewing, the finished product is ready to be used.

▼The Meiji era spinning machine “Garabo” (restoration machine) has the same mechanism as hand spinning, so it can spin very soft thread. For more information, see“Galabo has arrived at Hitotsuya! ”『ひとつ屋に「ガラ紡」がやってきました!』

▼ Of course, we sometimes hand-spun the harvested cotton to make products. This is a traditional Japanese spinning wheel.

Hitotsuya Silk

Sericulture, which has been carried out on a trial basis so far, will begin in earnest from 2023. Domestic silk production began by reclaiming abandoned farmland and cultivating mulberries. At Hitotsuya, we aim to make simple silk products using pre-modern manufacturing methods.

▼ Mulberries just planted at [Hitotsuya Dyeing and Weaving Farm]. For more information, please see”Hitotsuya Silk”. 『ひとつ屋シルク』.

▼ Sericulture was started while waiting for the mulberry trees to grow. For more information, please see”Hitotsuya Silk “Until the silkworm makes a cocoon” edition”. 『ひとつ屋シルク「蚕が繭を作るまで」編』。

▼ Cocoons harvested at Hitotsuya.

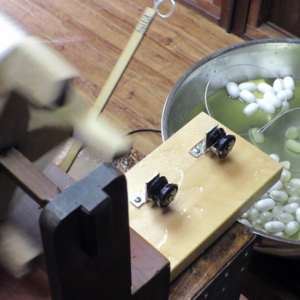

▼ At Hitotsuya, we use several methods to turn cocoons into thread. This is a “spot rotation”.

▼ This is “spinning”. For more information, please see Hitotsuya Silk “Until a cocoon becomes thread (spinning)”『ひとつ屋シルク「繭が糸になるまで(紡ぎ)」編』

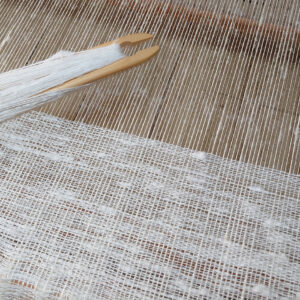

▼ The resulting yarn is then woven into shawls and other products. For more details, please refer to “Will our silk become a legitimate product?『自分たちのシルクが真っ当な製品になるのか』

others

In addition, Hitotsuya Dyeing Farm is also engaged in the cultivation of various dye plants (plants for herb-dyeing) such as indigo, Japanese akane, kariyasu, and kofunakusa, as well as the regeneration of “ancient cloth” made from ramie, kudzu, mulberry, and kozo.

▼ Harvesting of Japanese madder.

▼ Ramie collected and cultivated in Satoyama. For more information, please see [Hitotsuya Ancient Cloth Research Institute].【ひとつ屋 古代布研究所】

Hitotsuya’s thoughts

As mentioned above, Hitotsuya dyes and weaves using plants from dye farms and satoyama. We process them using traditional techniques that people have cultivated over time, and we aim to create products in which all of the materials, tools, and energy ultimately return to nature. We also hope to develop these products as “everyday items”.

In the future, Hitotsuya will report on the production process, gather new information from a wide range of sources, and hold workshops.

Thank you very much for your continued support of Hitotsuya.